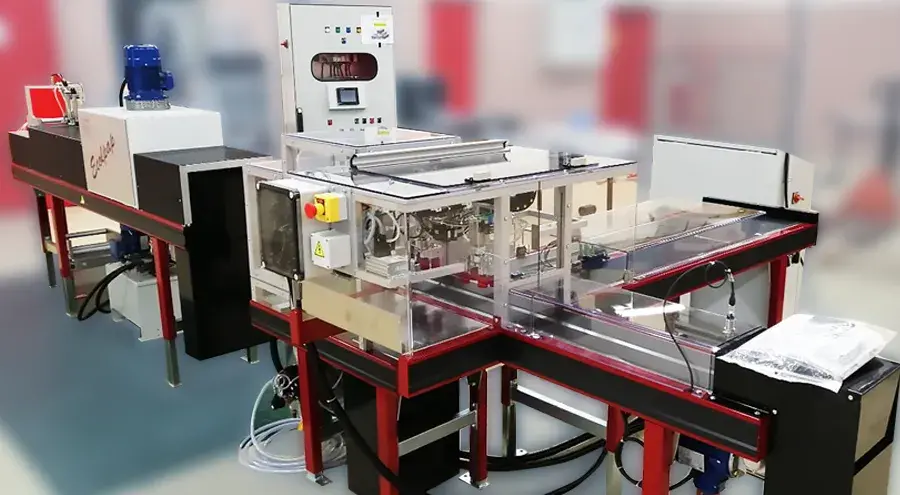

Ecolpap

Waste Paper Compacting System

ECOLPAP is a system for compacting waste paper from an A4 shredder.

It consists of seven functional sub-assemblies with complementary operations.

The shredded paper chips are compacted to form briquettes. They are then pushed one by one towards a filming unit associated with a thermo-regulated oven which ensures the shrinking of the film around the compacted shreds. This operation maintains the compactness of the briquettes and makes them easy to handle and re-group. The local control is carried out by a man/machine dialogue terminal which allows the manual start-up cycle, the visualisation of the adjustment cycle and the automatic production cycle, access to the counters and totalisers of the cycles and the pieces produced, access to the alarms and their acknowledgement, the choice of the production modes (normal and "despite everything").

Concept(s) associé(s)

EcolProd

Supervised production workshop A complete production process

<p style="text-align:justify">EcolProd is an educational workshop with a complete production process. Initially, the raw material is paper and/or wood chips in the form of briquettes, or wooden briquettes and the final product is a packaged and stored cardboard. It consists of several independent stations (from 1 to 4 independent stations). The energy used is electrical, pneumatic and hydraulic. Different types of automatons, communication by supervision.</p> <p style="text-align:justify">It allows to consider several operating modes: Preparation operation, Production all the same, Closing operation. This workshop manages two types of briquettes as well as two types of briquette packs and two types of cartons: paper briquettes (adjustable dimensions H. 20 to 50 mm), wood briquettes (fixed dimensions H. 20 to 50 mm), pack of one briquette, pack of two briquettes, carton of four briquettes per layer, carton of six briquettes per layer.</p>